Little Known Facts About Digital Printing.

Little Known Facts About Digital Printing.

Blog Article

The 30-Second Trick For Digital Printing

Table of Contents5 Easy Facts About Digital Printing DescribedDigital Printing Can Be Fun For AnyoneNot known Details About Digital Printing

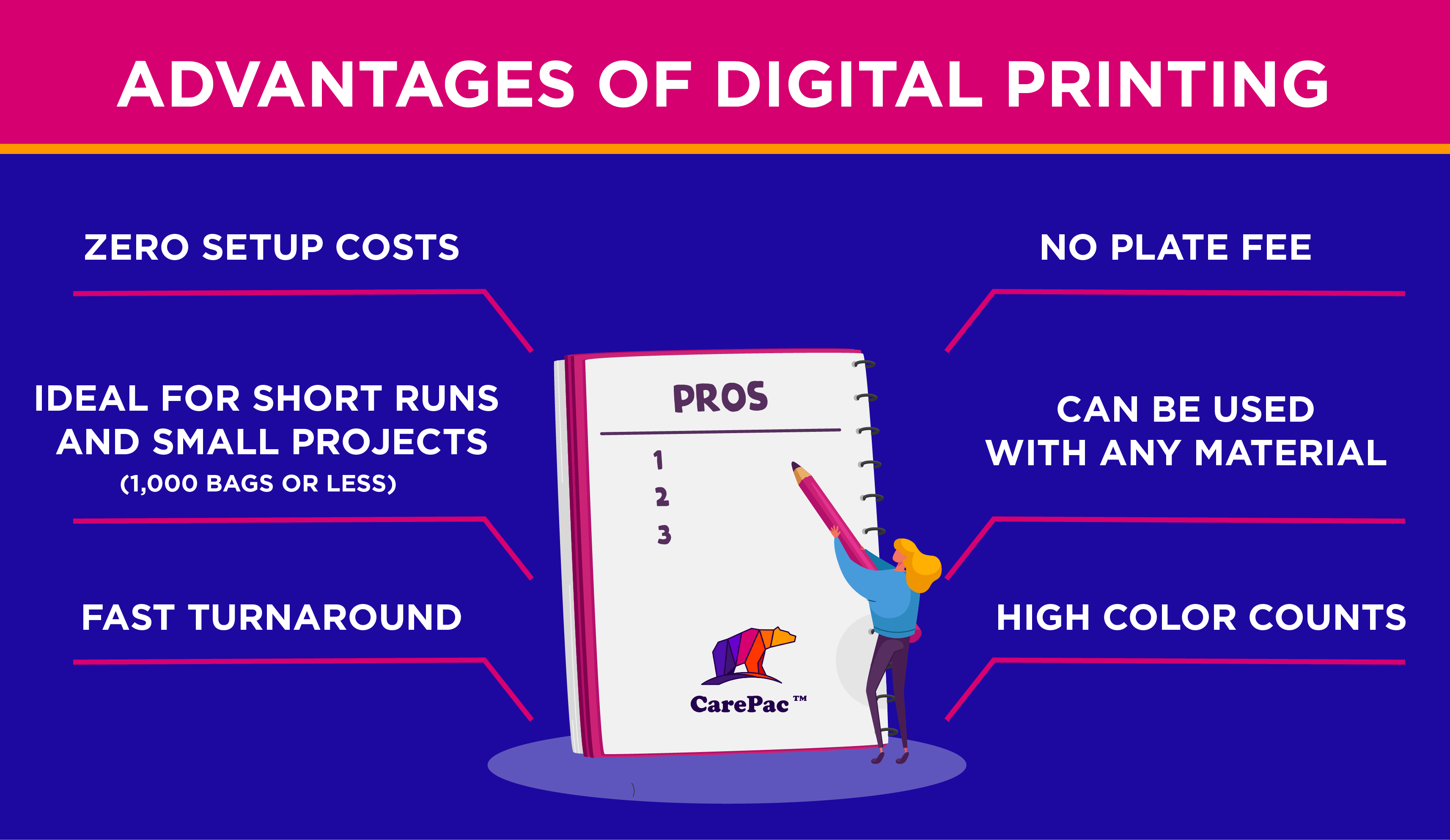

Digital printing likewise calls for very little configuration. Below are the essential ways in which electronic printing sustains greener practices: One of the substantial environmental advantages of digital printing is decreasing waste (Digital Printing). Standard printing methods, like lithographic printing, usually waste considerable amounts of paper and ink throughout the arrangement stage.

Digital printing presses remove the requirement for these plates, significantly lowering setup expenses. Digital printing presses can integrate variable information into your prints, which allows for very customized advertising and marketing materials (Digital Printing). By customizing your advertising materials, you can enhance involvement with potential consumers and enhance the opportunities of converting them into real clients

Digital printing presses use excellent shade uniformity and precision, causing better prints. With digital printing, you can be sure that the shade of your prints will correspond from one print work to the following. Numerous years earlier, several customers did decline direct-injection digital printing because the high cost. The acquisition price of an established electronic printing tools is at the very least 150%of the standard printing and dyeing devices, which enhances the.

What Does Digital Printing Mean?

In order to protect against deterioration of the nozzle, the ink for electronic printing is much more costly than the ink for standard printing, and extra ink filtration is needed throughout the printing process. In digital inkjet printing, the pattern is directly published on the material, eliminating the plate making in rotating display printing. Yes, click are extra pricey than standard printing inks, however the digital printing process can save ink intake.

Today, the digital direct-injection printing press has gone from proofing to the stage of medium-sized and large-sized manufacturing. The electronic direct-injection maker has actually gone with the promotion duration and got in the development and maturation period. Both printing houses and brand name proprietors know the development capacity of electronic printing, and want to boost investment in digital printing. The print top quality can occasionally also rival that of offset printing. Digital printing is extra cost-efficient for brief print runs due to the fact that it needs less pre-press tasks and less arrangement than countered printing. If a mistake in offset printing is not caught before home plates are made, it will be very costly to make new ones. While every person regards wishes that errors will certainly be prevented, it is reasonable to prepare for their prospective correction. In enhancement, its precision is really high. This makes certain uniformity in look throughout the board, lowering the possibility that any item will need to be tossed out due to defects. Making sure the plates are in area, the ink key is adjusted, and all the necessary changes have been his response made is a taxing process when offset printing. Decreased pre-press steps indicate much less time is needed to establish up the press. This leads to a significant velocity of turn-around time. When you need printed products rapidly, this is a fantastic choice. Digital printing can be a lifesaver when you obtain an order in the nick of time.

Variable data printing, such as straight mail with personalized codes and addresses, is preferably matched for digital printing. Digital quick printing just requires four steps of layout, review, printing and binding to obtain everything done. Digital quick printing has an unparalleled advantage: print on need.

Report this page